Hydrogen fuel cell solutions

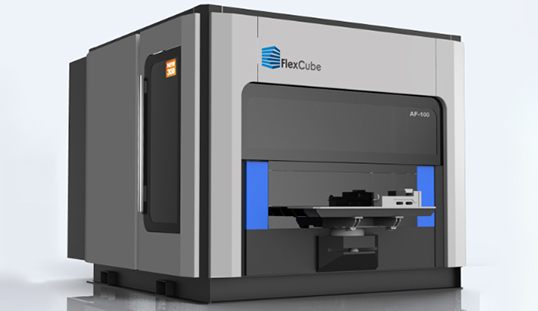

Power battery assembly and measurement solutions

Three-in-one motor assembly solution

Motor Controller Assembly Solutions

Engine Assembly Line Solutions

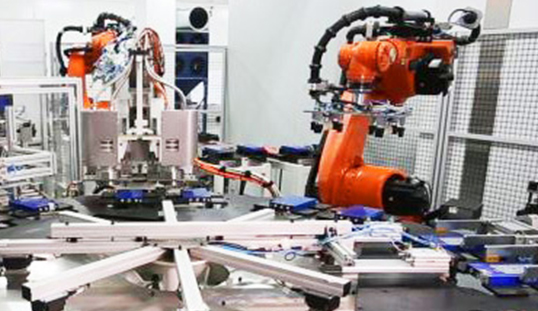

Robot Application Solutions

上(shàng)一頁

1

2

下一頁

Company address: No. 1089, Xuanzhen East Road, Pudong New Area, Shanghai

Site mailbox:sales@anwha-auto.com

contact number:021-68173509

Contact us

聯系我們

Description:

COPYRIGHT © 2021 Anwha (Shanghai) Automation Engineering Co., Ltd. ALL RIGHT SERVER