How to build an automated factory? Anwha Technology Conference gave the answer

- Categories:Corporate News

- Time of issue:2019-12-26 23:04

- Views:

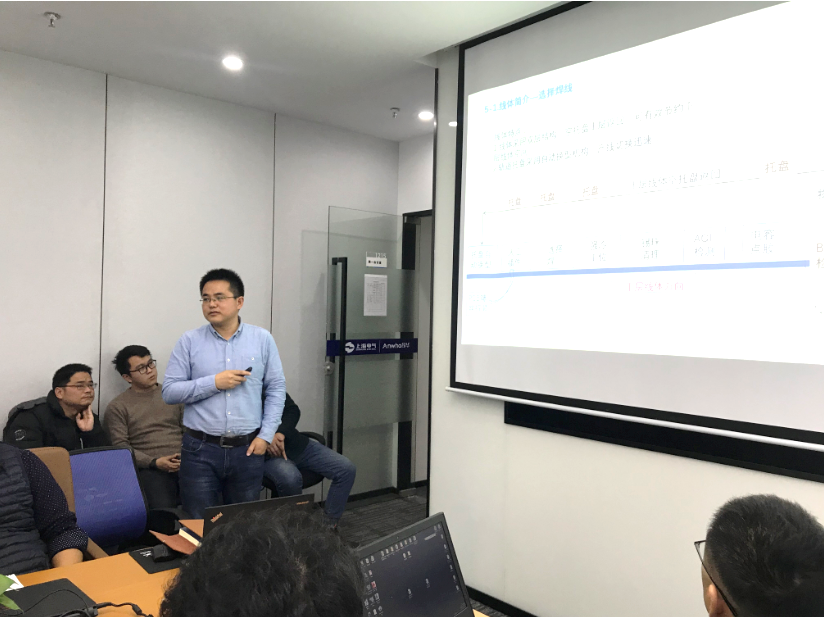

(Summary description)On December 25, 2019, the Anwha Technology Conference was held. More than 30 technical backbones from Anwha's executive team, R&D department, powertrain business department, new energy business department, and innovation business department participated in the meeting. With intelligent assembly as the core, they discussed the powertrain, new energy The application of various solutions such as three electricity, carbon fiber composite materials, vision systems, warehousing and logistics systems.

How to build an automated factory? Anwha Technology Conference gave the answer

(Summary description)On December 25, 2019, the Anwha Technology Conference was held. More than 30 technical backbones from Anwha's executive team, R&D department, powertrain business department, new energy business department, and innovation business department participated in the meeting. With intelligent assembly as the core, they discussed the powertrain, new energy The application of various solutions such as three electricity, carbon fiber composite materials, vision systems, warehousing and logistics systems.

- Categories:Corporate News

- Time of issue:2019-12-26 23:04

- Views:

The key to smart factories,

is to automate first,

How to automate a factory?

Anwha Technology Conference,

In-depth discussion on the high-tech of automated factories.

On December 25, 2019, the Anwha Technology Conference was held. More than 30 technical backbones from Anwha's executive team, R&D department, powertrain business department, new energy business department, and innovation business department participated in the meeting. With intelligent assembly as the core, they discussed the powertrain, new energy The application of various solutions such as three electricity, carbon fiber composite materials, vision systems, warehousing and logistics systems.

Anwha's "turnkey" solution in factory automation

• Powertrain: including engine, motor controller, flat wire motor rotor and assembly solutions. The engine assembly line provided by Anwha can realize standardized and modular design, shorten the delivery time, and help customers put products into production quickly; the motor controller assembly line provided by Anwha can be switched in parallel with two rails, which is not only compatible with different processes, but also has space for capacity expansion. Help customers cope with changing market demands; the flat wire motor assembly line provided can realize flexible process sequence and use industrial design to improve the appearance of equipment, help customers achieve multi-variety production and meet high industry standards. The concept of quick changeover, centralized feeding, flexible production and lean production were shared.

• Three new energy sources: including power battery modules and battery packs, motors, and electronic control assembly solutions. The module assembly high-speed line we provide can achieve high-speed production, high degree of automation, and high integration, helping customers to provide the largest possible production capacity in a limited space; the battery packaging and wiring provided can achieve standardized and modular design, shortening Delivery time, help customers respond quickly to the market. The high-speed line technology, full-component cleaning technology, full-component gluing technology, as well as the history and future development trends of battery modules and battery packs were discussed at the meeting.

• Carbon fiber composite material: Carbon fiber composite material processing cells and assembly lines can achieve high reliability and automated solutions to ensure the production consistency of customers' products. The meeting shared the precise control of robots to ensure product quality; under the existing standard station design concept, the overall design style has been iterated over and over and integrated into the industrial design concept; offline simulation can find and improve problems at any time.

• Vision system: The vision system includes 2D and 3D vision systems to help customers detect and control product quality, solve practical problems closer to the customer's production site, and provide customers with better after-sales service. Shared two-dimensional imaging technology, two-dimensional detection technology, and three-dimensional detection technology.

• Warehousing and logistics: an intelligent warehousing and logistics management system integrated with a three-dimensional warehouse system, AGV logistics and transportation system and MES information control system, can create a more integrated and efficient overall solution for customers, through advanced control and information technology applications, coordination All kinds of equipment actions realize automatic warehouse entry and exit operations, and realize warehouse information automation and refined management. During the meeting, implemented cases and future development plans were discussed.

As the competitive advantage of the global manufacturing industry shifts from cost to technology, technological innovation is the core driving force of the manufacturing industry. Through this technical conference, Anwha promotes technical personnel to explore and innovate from practice, and the improvement of technological innovation ability will help to improve production technology, reshape production process and improve production efficiency, thereby creating more value for customers.

Scan the QR code to read on your phone

相關新聞

Company address: No. 1089, Xuanzhen East Road, Pudong New Area, Shanghai

Site mailbox:sales@anwha-auto.com

contact number:021-68173509

Contact us

COPYRIGHT © 2021 Anwha (Shanghai) Automation Engineering Co., Ltd. ALL RIGHT SERVER