How the future-oriented Liuji engine line is made - Anwha's craftsmanship

- Categories:Corporate News

- Time of issue:2018-07-13 23:04

- Views:

(Summary description)A well-known OEM intends to build a future-oriented engine production line, and Anwha regards customer requirements as its mission. By adopting high-tech, the assembly line is more automated, intelligent and flexible, and successfully realizes the upgrade of intelligent manufacturing.

How the future-oriented Liuji engine line is made - Anwha's craftsmanship

(Summary description)A well-known OEM intends to build a future-oriented engine production line, and Anwha regards customer requirements as its mission. By adopting high-tech, the assembly line is more automated, intelligent and flexible, and successfully realizes the upgrade of intelligent manufacturing.

- Categories:Corporate News

- Time of issue:2018-07-13 23:04

- Views:

A well-known OEM intends to build a future-oriented engine production line, and Anwha regards customer requirements as its mission. By adopting high-tech, the assembly line is more automated, intelligent and flexible, and successfully realizes the upgrade of intelligent manufacturing.

Whole line at a glance

Assembly Line Name: Engine Assembly Line

Main models: in-line 4-cylinder, in-line 3-cylinder

Production takt time: assembly line off-line takt ≤ 90 seconds, semi-automatic/manual workstation takt ≤ 90 s, fully automatic workstation takt ≤ 72 seconds.

Fully automatic vacuum feeding

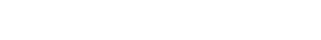

3D Vision Scanning

flexible tray

Connecting rod cap loosened

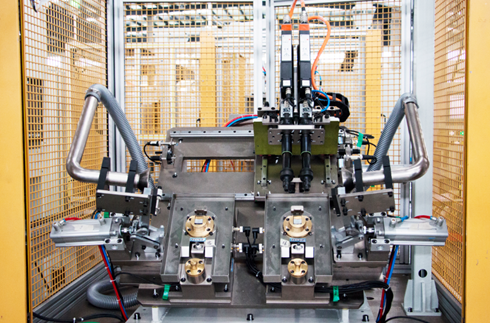

Standard manual workstation

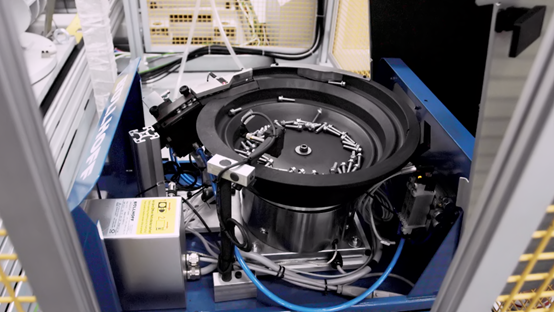

Clamp Press

The camera detects that the flywheel is tightened

Piston pin circlip press fit

The whole line conveying system includes: internal and external wire line roller table, cylinder head line roller table, piston connecting rod line roller table. The inner and outer assembly line adopts bevel gear transmission technology to ensure a long service life and maintenance-free. The piston connecting rod line adopts the upper and lower double connecting rod line, which fully takes into account the optimization of the customer's workshop space. The AGV adopts an automatic scheduling system to connect the pulling of materials between the interior, exterior and cylinder head lines.

The whole line is divided into: parts assembly area, cleaning, cylinder head, sub-assembly, piston connecting rod line sub-assembly, interior assembly, exterior assembly and other areas.

Highlights of the entire assembly line:

1. The whole line adopts three-dimensional vision system for inspection and error prevention. Using multiple sets of three-dimensional visual inspection, comprehensive inspection is carried out for the key whole-line assembly process.

2. The whole line production unit adopts modularization and standardization. Using multiple robots to achieve ultra-flexible assembly process, it is convenient for customers to update, compatible and iteratively upgrade different products in the later stage.

3. The flexible folding arm crane is adopted to make manual loading and unloading easier, easier and more efficient. Moreover, it can save the existing space of the workshop and has a hovering function.

After one year of this project, the powertrain Liuji project team worked hard day and night to keep improving every link, so that the project has successfully completed the acceptance. To ensure that customers can achieve engine mass production as soon as possible.

It is the craftsman spirit of Anwha that continuously creates value for customers and has also been widely recognized by customers.

Scan the QR code to read on your phone

相關新聞

Company address: No. 1089, Xuanzhen East Road, Pudong New Area, Shanghai

Site mailbox:sales@anwha-auto.com

contact number:021-68173509

Contact us

COPYRIGHT © 2021 Anwha (Shanghai) Automation Engineering Co., Ltd. ALL RIGHT SERVER